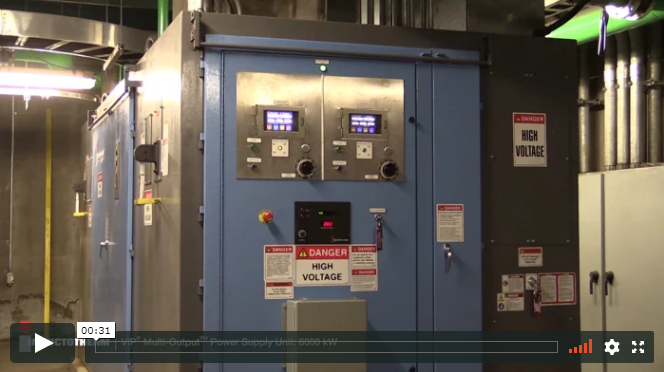

VIP Multi-Output Power Supply Units

Power two or more furnaces simultaneously for greater production with VIP™ Multi-Output™ Power Supply Units while offering the same great metal quality and superior operational flexibility with lower operating costs.

Features

VIP™ Multi-Output™ Power Supply Units, like our Dual-Trak™, Tri-Trak™ and Quad-Trak™ Power Supply Systems, can power two or more furnaces simultaneously for greater production with a minimum investment for each ton of metal being poured. Some of the many advantages include:

- A single power unit with the batch production capacity of multiple units

- Uninterrupted melting and precise temperature control for holding or superheating

- Ability to simultaneously preheat, sinter, melt and/or hold in multiple furnaces

- Increased alloy flexibility

- Equipment power utilization levels approaching 100 percent

- Increase metal production without increasing power demand levels

- Separate sets of controls for each furnace

- Ability to efficiently match production to varying levels of metal demand

- Only one set of power and water connections needed, greatly reducing installation, operation and maintenance costs

- The ability to direct full rated power to one furnace while fully isolating another during maintenance

Tech Specs

| Power Ranges | Up to 24 Megawatts |

| Contact Inductotherm for Custom Solutions | |

| Standard Features | Precise and Responsive Digital Controls |

| Digital Control Board with Fiber-Optic Clear Signal Processing | |

| Touch-Screen Display for Control and Data Entry | |

| Built-In Ground and Leak Detector System | |

| 6, 12, 24 or 48 Pulse Line Power Rectifier System | |

| Informative Diagnostics | |

| Power Control Adjustable at all Power Levels, Manual or Automatic | |

| Optional Features | System Status Text Messaging |

| Melt-Manager™ Plus™ Control Systems | |

| Factory Tested | Critical Components |

Control Options

Melt Shop Control Systems enable you to take control by monitoring and controlling the melt, diagnosing faults, maximizing power usage, minimizing power/fuel charges and performing a variety of tasks. We offer a variety of control system options which include:

- Melt-Manager™ Control Systems are our entry level to smart systems that utilize embedded microprocessor controls and provide the operator with melt control modes and diagnostics for analysis and support.

- Melt-Manager™ Plus™ Control Systems are computer-based applications which provide a higher level of melt automation technology to support furnace melt controls, diagnostic analysis and customer network, and communication interface.

- Meltminder™ 300™ Melt Shop Control and Management Systems provide the highest level of melt automation technology to support precise, highly responsive and fully programmable control, which is important to the safe and efficient operation of today’s induction melting equipment.