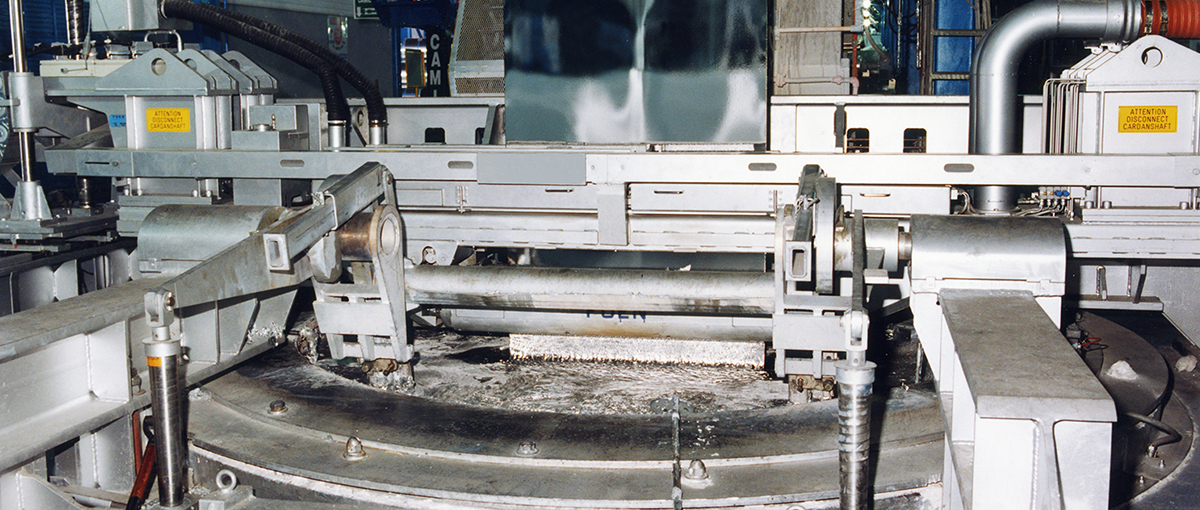

Coreless Coating Pots

Coreless Coating Pots are available for all coating applications. They are recommended for multiple alloy coatings, particularly when producing aluminum zinc and other aluminum alloy coatings, as they eliminate the relatively frequent inductor changes associated with these coatings.

Features

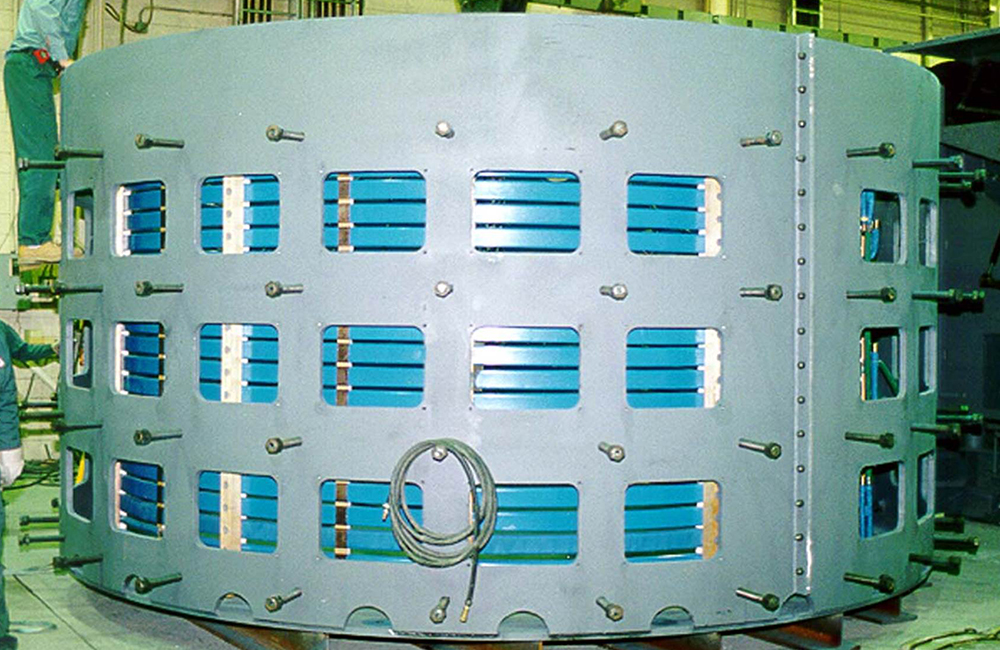

Coreless Coating Pots feature our patented coil design which extends the coil below the bottom of the bath to provide superior magnetic coupling and stirring of the metal. Due to their superior stirring effects, our Coreless Coating Pots are able to achieve higher-power density levels than traditional channel pots, minimizing the necessary overall capacity required to meet production demands. This translates to cost savings through reduction in raw material requirements and lower energy requirements. Features include:

- A rugged design that withstands the most severe mill environments

- A circular design which provides excellent refractory support while minimizing required capacity

- A single inductor coil which is enclosed in a heavy steel shell for additional protection

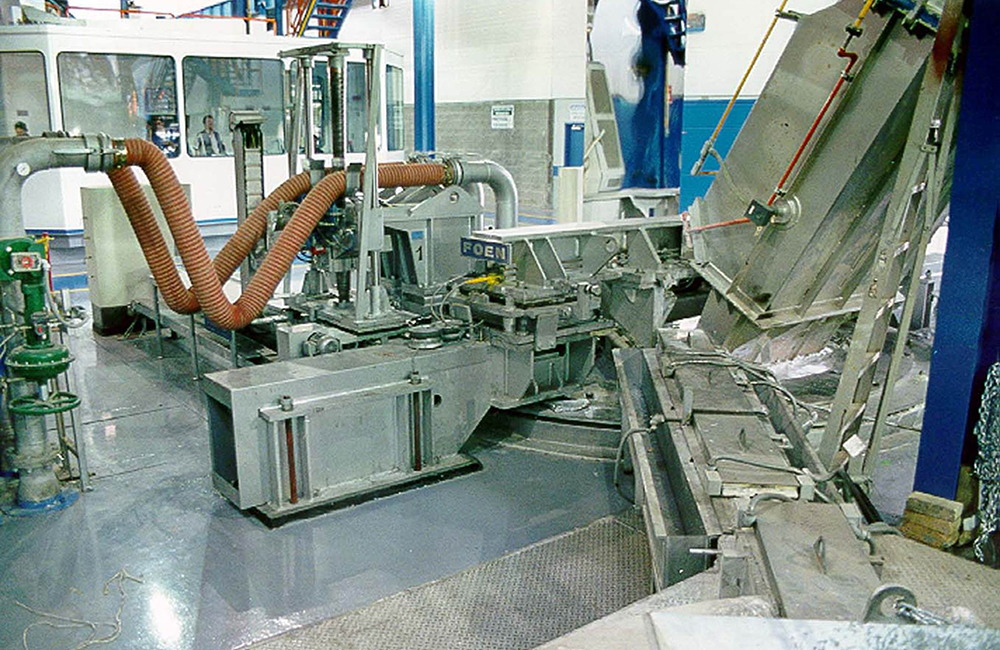

- Bogies and lift options that are available for pot movement for multiple pot installations

Tech Specs

| Capacities | 10 to 130 Metric Tons [11 to 143 Short Tons] of Molten Zinc Holding Capacity |

| Contact Inductotherm for Custom Solutions | |

| Standard Features | Solid-State VIP™ Power Supply Units with SCR Technology |

| Water Cooling Systems with Emergency Backup | |

| Molten Metal Leakage Detection | |

| Optional Features | Insulated Pot Covers |

| Metal Level Measurement and Monitoring | |

| Communication Options via a Variety of Industrial Protocols | |

| Moveable Pot Designs for Multi-Pot Installations | |

| Pot Lifting Systems for Multi-Pot Installations | |

| Advanced Stirring Control | |

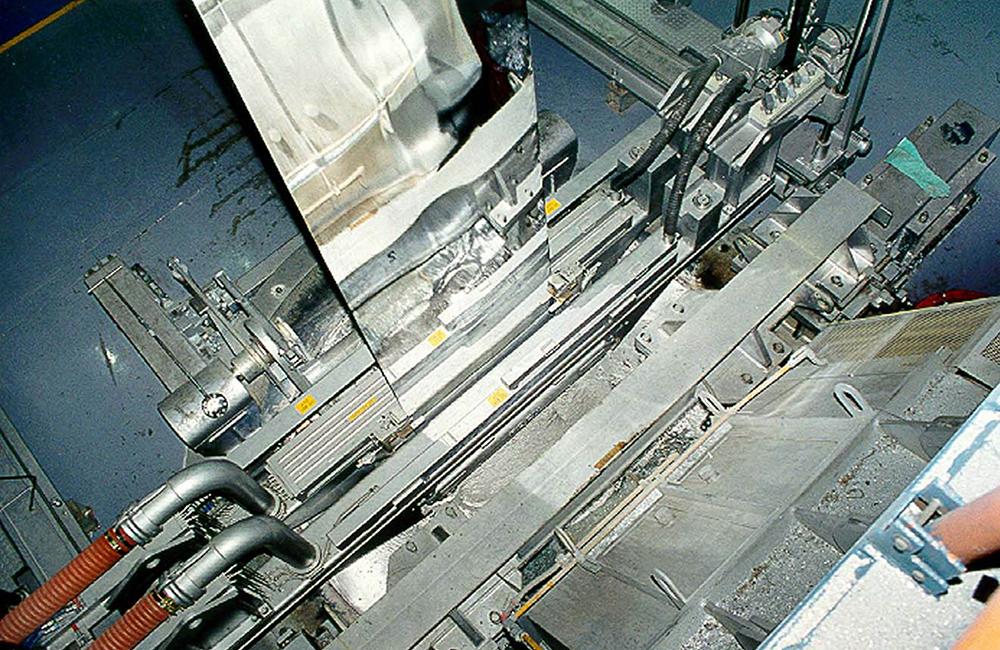

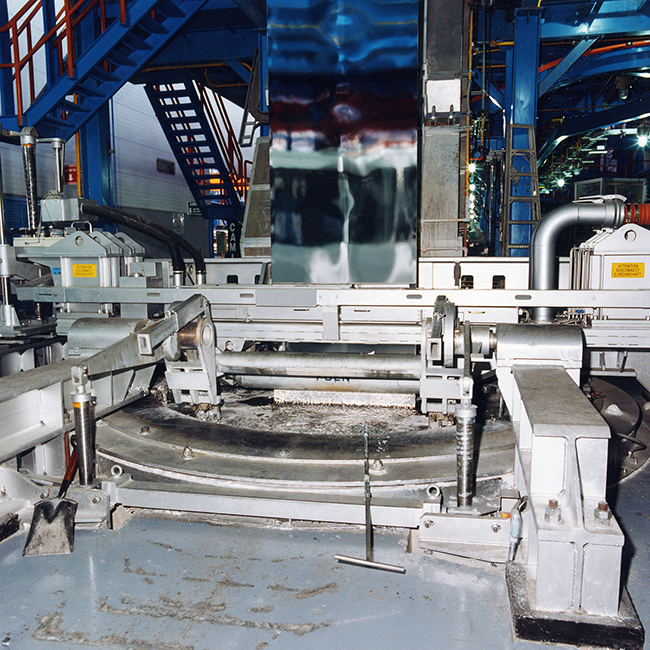

| Automated Robotic Dross Removal Provided by the ARMS™ System | |

| Factory Tested | Critical Components |